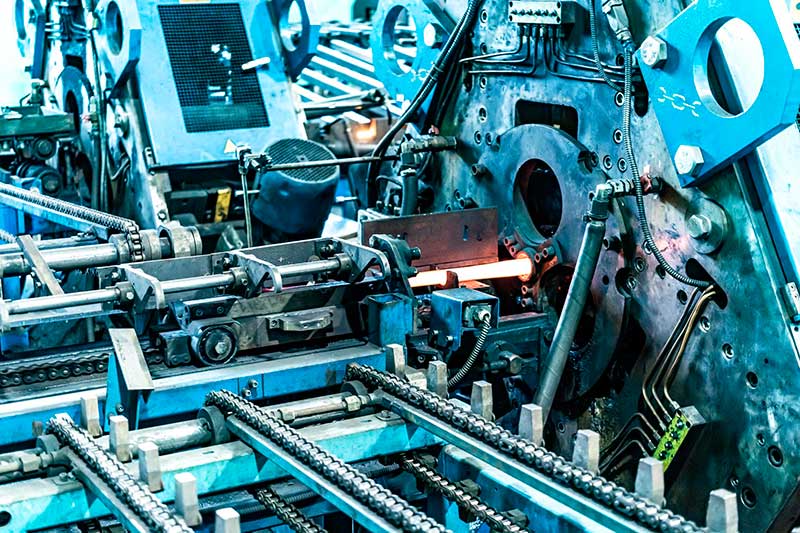

Setting up an industrial production line requires careful planning, coordination, and execution to ensure smooth operations and optimal efficiency. Whether establishing a new manufacturing facility or upgrading an existing production line, several key steps are involved in the process.

- Assessment of Production Requirements: The first step in setting up an industrial production line is to assess the production requirements, including expected output volume, product specifications, and quality standards. This information helps determine the type and capacity of equipment needed for the production process.

- Selection of Industrial Equipment: Based on the production requirements, companies select the appropriate industrial equipment, such as conveyors, robots, assembly stations, and packaging machinery. Factors like reliability, performance, and compatibility with existing systems are considered during equipment selection.

- Layout Design and Installation: The layout of the production facility is designed to optimize workflow, minimize material handling, and ensure efficient use of space. Equipment is installed according to the layout plan, taking into account factors like access for maintenance and safety considerations.

- Integration and Testing: Once the equipment is installed, it is integrated into the production line and tested to ensure proper functionality and performance. This may involve adjusting settings, calibrating sensors, and conducting trial runs to identify any issues or inefficiencies.

- Training and Certification: Personnel responsible for operating and maintaining the production line receive training on equipment operation, safety protocols, and troubleshooting procedures. Training programs may be conducted by equipment manufacturers or certified trainers to ensure competency and compliance with industry standards.

- Implementation of Maintenance Plans: Establishing a preventive maintenance schedule is crucial to prolonging the lifespan of industrial equipment and minimizing downtime. Regular inspections, lubrication, and repairs are performed according to the maintenance plan to address potential issues before they escalate.

- Continuous Improvement: Once the production line is operational, ongoing monitoring and performance analysis are conducted to identify opportunities for optimization and efficiency improvements. Feedback from operators and maintenance personnel is valuable for identifying areas of improvement and implementing corrective actions.

In conclusion, setting up an industrial production line requires a systematic approach that involves careful planning, equipment selection, installation, training, and maintenance. By following best practices and leveraging advanced technologies, companies can optimize their production processes, enhance productivity, and achieve their manufacturing goals.